The Lab Miami 400 NW 26th Street Miami, FL 33127

Presenters

Eric Goldemberg – Associate Professor, FIU School of Architecture Oscar Glottman – Glottman

Ken Baker – Assistant Professor, UM Department of Mathematics Corrie Van Sice – Creative Research and Engineering

Werner Blumenthal – WB Engineering

http://soa.fiu.edu/architecture/faculty/eric-goldemberg/

http://www.math.miami.edu/~kenken/ http://corrievansice.com/

http://pixil3d.com/

A newbie to Miami recently asked me if Miami was alive with activity. Absolutely, if you know where to go! 3D is intriguing for me, so I went to The Lab to hear more on this. On Sept 20 we had a riveting PechaKucha night with 3D printing experts discussing 3D printing developments in the education, medical, and corporate sectors.

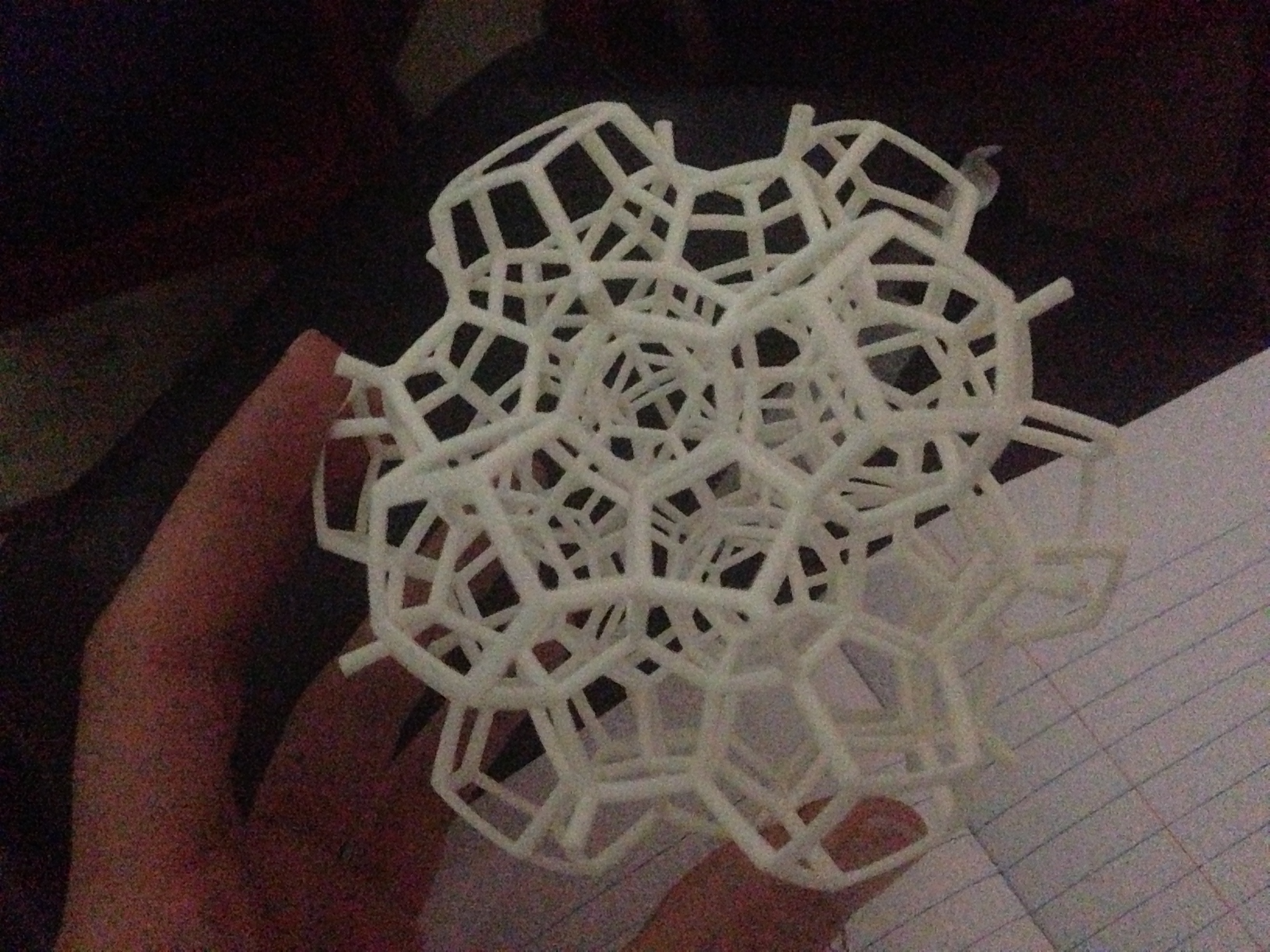

It was also a night of reflection, creativity, and methodology. A step back from simply seeing results of 3D printing. Presenters discussed innovation of their other contraptions and machines some which they explained followed the protocols such as those found in “Mechanism of Life” (S Leduc, 1911) and emulating chemical processes (as in synthetic biology) as complex as cell division. To one presenter, “matter is full of energy and life is made of stuff, and stuff can thereby be designed”. Using this principle, we saw an interesting machine that through electricity grows bone. We heard that through the understanding of the physics of materials, and applying specific methods and processes to the making of a machine, computing or code these can then create’ the impossible’. We saw examples of this too like Anthony Atala’s printed liver (http://www.ted.com/talks/anthony_atala_printing_a_human_kidney.html) or the printed 3D bionic ear, which timely enough I had just read about (http://mashable.com/2013/05/24/3d-printed-ear-princeton/) or the sheep that milk spider silk for commercial use, an insightful documentary I had seen back in London (http://www.bbc.co.uk/news/science-environment-16554357).

There is infinite possibility and infinite improvement, so folly to our presenter, is…. inevitable. This we know, and this is where the idea that has generated in 3D printing has built some businesses.

Enter Blumenthal Engineering which exists on the premise of early simulation. WB Engineers test and validate their clients’ digital designs upfront to catch design flaws before the manufacturing phase. They claim between 70-80% of cost can be saved if simulated digitally first. We got a first-hand view into some of the types of simulation they use and why each process is ideal for specific objectives. No tool has it all.

– Fused Deposition Modeling (FDM)

– Film Transfer Imaging (provides a chemical change with a smooth finish, less porous) – Stereolithography (SLA) (provides high accuracy, and has different melting points)

– SLS and DMLS (resin solidifies razor)

– MJM + Polyjet (provides highest accuracy, thin layers and high detailed parts)

– Powder Binding (provides full colour printing – good for toys and architecture)

For a more and highly artistic approach, Oscar Glottman originally from Belgium and spearheading MGX Materialise originally built prototypes for medical and engineering fields, but now specialises in non-commercial 3D printing, from small and precise jewellery items to larger scale light fixtures and furniture. I saw some incredible art and urge you to look at his site http://www.glottman.com/?page_id=2521